1. Ke eng alehare la sakha la taemane

Lehare le chitja la taemaneke sesebelisoa sa ho seha se tloaetseng ho sebelisoa, e leng lehare la sakha le nang le moeli oa ho seha taemane le ka har'a selikalikoe se ka hare kapa se kantle sa lehare la sakha.E sebelisoa haholo ha ho etsoa lisebelisoa tse thata le tse brittle tse kang majoe le lirafshoa.Lehare la daemane haholo-holo le na le likarolo tse peli: substrate le lehare.Substrate ke karolo e ka sehloohong e tšehetsang lehare la sekhomaretsi, athe lehare ke karolo ea ho itšeha e qalang nakong ea tšebeliso.Lehare le tla lula le ja nakong ea ts'ebeliso, athe substrate e ke ke ea sebelisoa.Likaroloana tsa daemane li phuthetsoe ka tšepe ka har'a hlooho e sehang, e phethang karolo ea ho itšeha ho seha ha likhohlano tsa ntho e sebelitsoeng nakong ea ts'ebetso ea machining.Nakong ea ts'ebeliso, matrix ea tšepe le daemane li jeoa hammoho.Ka kakaretso ho loketse hore matrix a tšepe a je ka potlako ho feta daemane, e leng se tiisang hore ho na le bohale ba hlooho ea ho itšeha le bophelo ba tšebeletso ea hlooho ea ho itšeha.

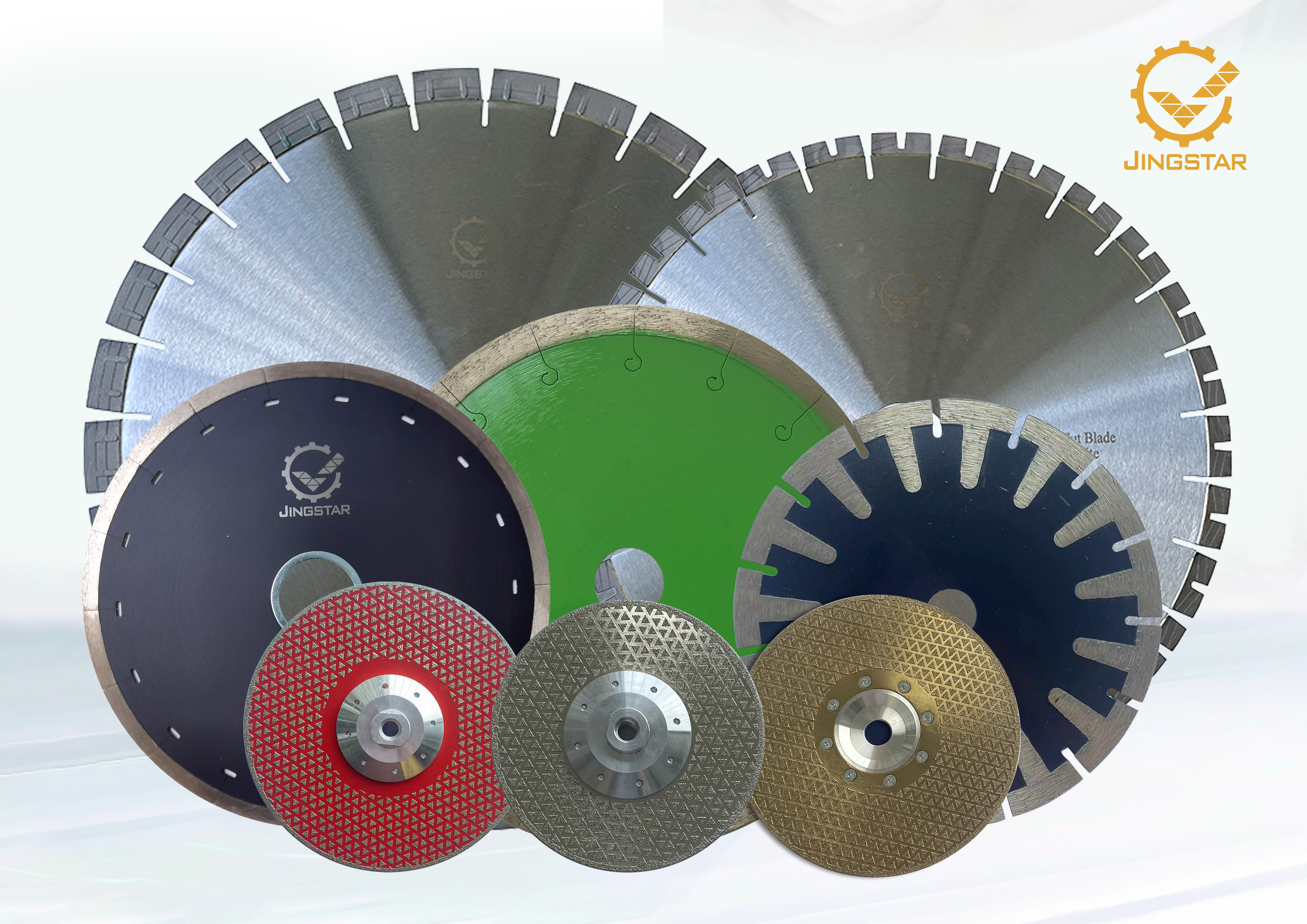

The bophara span eamahare a selikalikoe a taemanee khōlō, e nang le mahare a betliloeng a limilimithara tse ’maloa le mahare a maholo a sakha a bophara ba limithara tse ’maloa.Hape ho na le lintho tse ngata tsa ho itšeha, 'me sebopeho, boima, le boholo ba lintho tsa ho itšeha li fapana haholo.Ka hona, mekhoa ea bona ea ts'ebetso le tlhahiso, lisebelisoa tse tala tse sebelisoang, le litlhoko tsa ts'ebeliso li fapane.

2、 Sehlopha samahare a selikalikoe a taemane

Lehare le chitja la taemanehona joale ke sesebelisoa sa ho sakha se sebelisoang haholo indastering ea majoe ea China, eo ka kakaretso e leng sebopeho sa selikalikoe.E sebelisa mekhoa e joalo ka metallurgy ea phofo kapa electroplating ho kenya likaroloana tsa daemane ho potoloha substrate.Ho sebelisa matla a phahameng le ho thatafala ha likaroloana tsa daemane ho kuta le ho pshatla lisebelisoa tse ling bakeng sa merero ea ho itšeha.Ho na le mefuta e mengata eamahare a selikalikoe a taemanele ho aroloa ha tsona ho boetse ho rarahane haholo.Hangata ho na le mekhoa e mengata ea ho arola:

1. Ho hlophisoa ka mokhoa oa tlhahiso:

(1) Lehare la sakha la daemane

Ho na le mefuta e 'meli ea sintering: sintering e batang ea khatiso le hot sintering.

(2) Lehare la sakha la taemane le chesellang

Ho na le mefuta e 'meli ea brazing le laser beam welding.Brazing ke ho tjheseletsa hlooho ea seha le substrate hammoho ka mocheso o phahameng oa ho qhibiliha, joalo ka lehare le phahameng la induction brazing saw blade, vacuum brazing saw blade, joalo-joalo;Laser welding e sebelisa mocheso o phahameng oa laser bonding ho qhibilihisa hlooho e sehang le moeli oa ho kopana oa substrate ho theha bonding ba metallurgical.

(3) Lehare la taemane le kentsoeng ka motlakase

Ke mokhoa oa ho kopanya phofo ea lehare ho substrate ka electroplating.Leha ho le joalo, ka lebaka la tšilafalo e matla, naha butle-butle e felisa mokhoa ona oa electroplating.

2. Karolelano ka ho sebetsana le ntho:

Lehare la ho itšeha ka 'mabole, lehare la seha sa granite, lehare la seha sa konkreite, joalo-joalo.

3. Ho arola ka ponahalo:

Li-blade tsa saw, mofuta oa lehare, li-blade tsa mofuta oa turbine, joalo-joalo. Ha e le hantle, mokhoa ona o ka holimo o ke ke oa kenyelletsamahare a selikalikoe a taemane, hape ho na le merero e mengata e khethehilengmahare a selikalikoe a taemane.Khetha mefuta e fapaneng ea li-blades tsa daemane bakeng sa ho sebetsana le lisebelisoa tse fapaneng.

3、 Litšobotsi tse ka sehloohong tsalehare la sakha la taemaneho poma

Circle saw blade e na le melemo ea ts'ebetso e bonolo, ts'ebetso e phahameng, le boleng bo botle ba ts'ebetso.Empa lerata le lerata le ho tiea ha lehare ho fosahetse.Nakong ea ts'ebetso ea ho itšeha, lehare la sakha le atisa ho sisinyeha le ho kheloha, e leng se etsang hore ho be le ho se tšoane ho hoholo ha mosebetsi o sehiloeng.

4. Lintlha tse amang katleho le nako ea bophelo eamahare a selikalikoe a taemane

Lintlha tse amang katleho le nako ea bophelo eamahare a selikalikoe a taemanekenyeletsa mekhoa ea ho itšeha, kereiti ea daemane, boholo ba likaroloana, mahloriso le boima ba bond.

1. Mekhahlelo ea sawing

(1) Lebelo la ho seha saha

Mosebetsing o sebetsang, lebelo la mola oamahare a selikalikoe a taemanee lekanyelitsoe ke maemo a thepa, boleng ba lehare la saw, le thepa ea lejoe le sakhang.Mabapi le bophelo ba ts'ebeletso le bokhoni ba ho itšeha ha lehare la saw, lebelo la lebelo la lehare le lokela ho khethoa ho latela thepa ea majoe a fapaneng.

(2) Botebo ba ho sakha

Ka har'a mefuta e lumelletsoeng ea ts'ebetso ea mochini oa sakha le matla a sesebelisoa, botebo bo boholo ba ho itšeha bo lokela ho khethoa ka hohle kamoo ho ka khonehang ho ntlafatsa bokhoni ba ho itšeha.Ha ho na le litlhoko tsa sebaka se entsoeng ka mochine, ho lokela ho sebelisoa ho itšeha ha botebo bo fokolang.

(3) Lebelo la ho fepa

Lebelo la phepelo ke lebelo la phepelo la lejoe le sahiloeng.Boleng ba eona bo lokela ho khethoa ho itšetlehile ka thepa ea lejoe la sawn.Ha re bua ka kakaretso, ho sakha majoe a bonolo, joalo ka 'mabole, ho ka eketsa botebo ba ho sakha le ho fokotsa lebelo la phepelo, e leng se thusang ho ntlafatsa sekhahla sa ho sakha.Ho saha granite e nang le grained e ntle le e batlang e tšoana ho ka eketsa lebelo la fepa ka nepo.Haeba lebelo la phepelo le le tlase haholo, lehare la taemane le siloa habonolo.Leha ho le joalo, ha u sakha granite e nang le sebopeho sa lijo-thollo tse mahoashe le boima bo sa lekaneng, lebelo la ho itšeha le lokela ho fokotsoa, ho seng joalo le tla etsa hore lehare la sakha le sisinyehe le ho etsa hore daemane e arohane, kahoo e fokotsa sekhahla sa ho itšeha.

2. Taemane phatsa boholo

Boholo bo sebelisoang hangata ba daemane bo tloha ho 30/35 ho isa ho 60/80 mesh.Ha lejoe le thatafala, boholo ba likaroloana bo lokela ho khethoa.Hobane tlas'a maemo a tšoanang a khatello, daemane e ntle haholoanyane, e fetoha e bohale haholoanyane, e leng molemo bakeng sa ho khaola majoe a thata.Ntle le moo, ka kakaretso li-blade tse kholo tsa bophara li hloka bokhoni bo phahameng ba ho itšeha, 'me boholo ba likaroloana tse mahoashe joalo ka 30/40 mesh le 40/50 mesh li lokela ho khethoa;Maqhubu a manyane a saha a na le ts'ebetso e tlase ea ho seha 'me a hloka likarolo tse boreleli tsa ho seha mafika.Ho eletsoa ho khetha boholo ba likaroloana tse nyane, joalo ka 50/60 mesh le 60/80 mesh.

3. Tšebeliso ea daemane

Taemane ea mahloriso e bolela ho teteana ha kabo ea taemane ka har'a matrix a lera le sebetsang.Ho ea ka melao ea tsamaiso, mahloriso a 4,4 carats ea daemane ka li-cubic centimeter ea ho sebetsa lera matrix ke 100%, 'me mahloriso a 3.3 carats ea daemane ke 75%.Khatello ea molumo e emela bophahamo ba daemane ka har'a boloko mme e bolela hore mahloriso ke 100% ha molumo oa litaemane o nka 1/4 ea molumo kaofela.Ho eketsa bongata ba daemane ho lebelletsoe ho lelefatsa nako ea bophelo ea lehare la sakha, kaha ho eketsa khatello ho fokotsa matla a ho itšeha ka daemane ka 'ngoe.Empa ho eketsa mahloriso ho tla eketsa litšenyehelo tsa lehare la sakha, ka hona ho na le khatello e phahameng ea moruo e ntseng e eketseha ka keketseho ea ts'ebetso ea lisakha.

4. Ho thatafala ha sekoahelo sa hlooho:

Ha re bua ka kakaretso, ho ba le boima bo phahameng ba bond, ho matlafala ha eona ho hanyetsa ho apara.Ka hona, ha u bona majoe a nang le abrasiveness e phahameng, ho thatafala ha binder ho phahame habonolo;Ha u saha majoe a bonolo, ho thatafala ha binder ho lokela ho ba tlaase;Ha u sakha majoe a nang le abrasiveness e phahameng le boima, boima ba binder bo lokela ho ba bo itekanetseng.

5、 Mokhoa oa Ntlafatso eaLi-Diamond Circle Saw Blades

Maqhubu a selikalikoe a taemaneke lisebelisoa tse ka sehloohong indastering ea ho sebetsa ka majoe.Lilemong tsa morao tjena, palo ea litaemane tsa maiketsetso tse sebelisoang indastering ea ho lokisa majoe e eketsehile haholo, 'me tšebeliso eamahare a selikalikoe a taemanele eona ea eketseha.Ka kakaretso, ntshetsopele yamahare a selikalikoe a taemaneka hare ho naha le linaheng tse ling e na le litšobotsi tse latelang: ho hlahisa li-blade tse sebetsang hantle le tsa boleng bo phahameng, le ho hlahisa litaemane tse khethehileng tsa sehlopha sa saw blade;Ela hloko haholoanyane lipatlisiso tsa phofo, matrix, le mokhoa oa sintering;Ela hloko haholoanyane ho etsa lipatlisiso ka mokhoa o tšoanang le oa sawing oa thepa ea majoe;Laser tjheseletsa saha lehare e se e ntshetswa pele;Hlahisa ho feta boholomahare a selikalikoe a taemane.Hajoale, ts'ebeliso eamahare a selikalikoe a taemanee ntse e ata ka ho eketsehileng.Nakong e tlang, tataiso ea ntlafatso eamahare a selikalikoe a taemaneke ho ntlafatsa bokhoni ba ho itšeha, bophelo ba blade ea sakha, ho fokotsa litšenyehelo tsa tlhahiso, le ho fihlela ts'ireletso ea tikoloho.

Reference: "Diamond le Diamond Tools Tsebo Q&A" ka Zhang Shaohe le Hu Yule

Nako ea poso: Aug-04-2023